- ● Introduction

- ● Particle Size Analyzer

- ● Measurement principle

Introduction

The particle size distribution is a crucial parameter in many applications that involve powders or dispersions, such as construction materials, pharmaceuticals, ceramics, colored pigments, fertilizers, and emulsions. As the range of applications expands, so do the requirements for measuring methods in terms of size range, measurement time, and reproducibility.

Measuring particles close to the measurement range limits and simultaneously detecting particle sizes of both small (nanometer range) and large particles (millimeter range) for polymodally or broadly distributed samples is particularly challenging. However, modern laser diffraction particle size analyzers such as the Bettersizer S3 Plus overcome these challenges through innovative optical system design that detects backscattered light of very small particles and captures large particles with an integrated high-speed CCD camera, realizing a combination of laser diffraction technology and image analysis.

Particle Size Analyzer

Bettersizer S3 Plus

Particle Size and Shape Analyzer

Measurement range: 0.01 - 3,500μm (Laser System)

Measurement range: 2 - 3,500μm (Image System)

Bettersizer 2600

Laser Diffraction Particle Size Analyzer

Measurement range: 0.02 - 2,600μm (Wet dispersion)

Measurement range: 0.1 - 2,600μm (Dry dispersion)

Measurement range: 2 - 3,500μm (Dynamic imaging)

Bettersizer ST

One-stop Particle Size Analyzer

Dispersion type: Wet

Measurement range: 0.1 - 1,000µm

Repeatability: ≤1% variation

Measuring Method

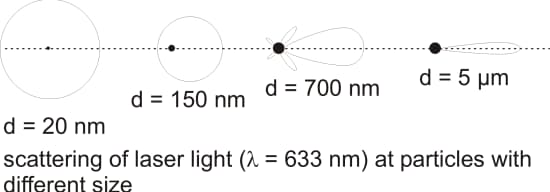

Laser diffraction method of particle sizing involves the interaction of laser (monochromatic and coherent light) with particles that need to be measured in terms of their size. The diffraction of light waves by the particles follows a distinct pattern depending on their size: larger particles scatter more light in the forward direction. For particles smaller than 100 nm, the scattering intensity is almost the same in all directions.

Laser diffraction at particles with different size

The scattering intensity is determined by stationary detectors depending on the angle. State-of-the-art laser diffraction systems such as the Bettersizer S3 Plus laser diffraction particle size analyzer guarantee the determination of scattering intensities in a continuous angular range of 0.02 – 165°, i. e. in the forward, side, and backward direction. This is achieved by means of the unique Dual Lens and Oblique Incidence (DLOI) optical system: Fourier lenses (collective lens) are positioned between the laser and particles as well as between particles and detectors. The particles will interact with the light within a parallel laser beam. This offers the advantage that the scattered light can also be detected at very large angles (in the backward scattering direction) and thus even very small particles can be detected and measured precisely. Thanks to DLOI technology, the problems of conventional measurement setups can also be avoided. Therefore, neither the suitable lenses for the corresponding particle size measurement range have to be selected prior to the measurement (in comparison to the Fourier optics), nor do measurement inaccuracies result from different particle-to-detector distances if not all particles lie in one plane (in comparison to the inverse Fourier optics).

Schematic drawing of the innovative DLOI technique of Bettersizer S3 PLUS and CCD-camera system (x0.5 and x10)

To calculate the particle size distribution from the measured scattering spectra, the theory of either FRAUNHOFER or MIE is applied. The FRAUNHOFER theory is based on the hypothesis of opaque and spherical particles: the scattered pattern corresponds to a thin opaque two-dimensional plate – diffraction only occurs at the edges. Therefore no additional optical input constants of the material are necessary for this calculation. In contrast, the MIE theory uses the hypothesis of virtually translucent and spherical particles, meaning that light permeates the matter and is scattered elastically at the atoms of the particle. The knowledge of the complex refractive index of the particles and the liquid as well is necessary. This theory is applicable to particles of all sizes.

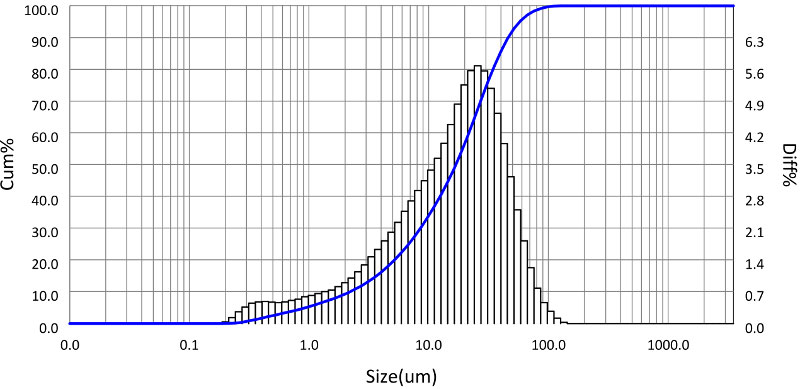

The following figure shows an example of a volume-weighted particle size distribution of a calcium carbonate powder – measured with a Bettersizer S3 Plus. The cumulative throughput curve (blue line) and the resulting histogram (black bar) can be seen.